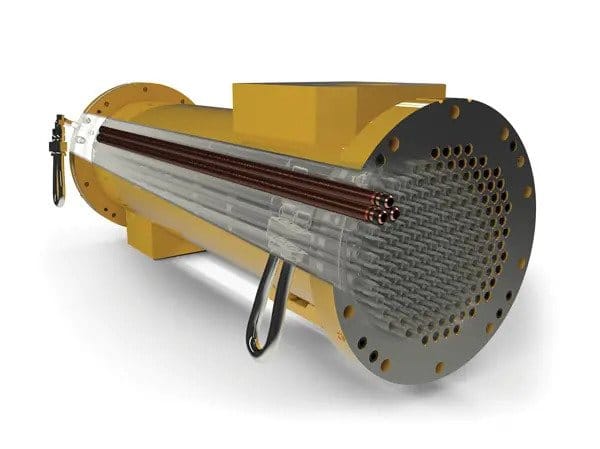

System Protector™ Tube and Shell Cooler

YOUR SAFEGUARD AGAINST CROSS-CONTAMINATION

FOR SYSTEMS UNDER CONTINUOUS OPERATION

Cross-contamination issues result in an expensive engine, brake, or transmission repairs. MESABI® System Protector™ provides an added safeguard for these systems, preventing damage and costly downtime to your equipment.

HIGHER COOLING PERFORMANCE POTENTIAL

IF APPLICATION REQUIRES HIGHER COOLING PERFORMANCE, SMALLER TUBE CONFIGURATIONS ARE AVAILABLE.

DUAL-SEAL SAFEGUARD

EACH TUBE END FEATURES TWO SEALS AND A COLLECTION CHAMBER TO PREVENT FLUID CROSS-CONTAMINATION.

NO LEAKY

SOLDERED SEAMS

MESABI® SEALS ABSORB STRESS, VIBRATION, SHOCK AND THERMAL EXPANSION.

100% REPAIRABLE

IN THE FIELD

INDIVIDUAL TUBES ALLOW FOR EASY IN-FIELD REPAIR. REFER TO RESOURCES FOR SERVICE VIDEOS.

MULTIPLE LEAK ALERTS

SIGHT GAUGE STANDARD WITH OTHER DETECTION OPTIONS AVAILABLE.

INDUSTRY BEST

SEAL WARRANTY

48-MONTH WARRANTY AGAINST SEAL LEAKAGE.

MAXIMUM

SERVICEABILITY

MINIMAL MAINTENANCE DESIGN FEATURES A CLEAN

OUT ACCESS DOOR FOR EASY AND EFFECTIVE

CLEANING FROM THE INSIDE OF THE SYSTEM.

Safeguard Insurance Like No Other: No More Cross-Contamination Thanks to Exclusive System Protector Tube and Shell Cooler

For reliable 24/7 systems operation, Mesabi® System Protector Tube and Shell Coolers engineered by L&M Radiator are the answer.

With exclusive leak alert detection, Mesabi System Protector Tube and Shell Coolers eliminate costly cross-contamination damage and downtime issues with an exclusive dual-seal tube end safeguard and a collection chamber to prevent fluid cross-contamination, preventing expensive engine, brake, or transmission repairs.

Built to endure higher pressures, extreme temperature, thermal expansion, vibration and shock stresses, Mesabi System Protector Tube and Shell Coolers eliminate the potential for leaky soldered seams. Maximum temperatures include water at 240ºF and oil at 275ºF and operating pressures of tube side: 50 psi (345kPa) and shell side: 150 psi (1034kPa), with additional pressures available.

In conventional cooling systems, thermal fatigue and mechanical stress can lead to leaks, which in turn can cause expensive downtime. Mesabi System Protector Tube and Shell Coolers combat thermal and mechanical stress and fatigue with L&M Radiator grommeted rubber seal ingenuity in engine, brake, and transmission coolers. Proven time and time again to withstand whatever comes their way, these seals are backed by L&M’s industry-best warranty.

Mesabi System Protector Tube and Shell Coolers can be customed designed to meet a customer’s needs with a range of shell diameters and two different tube diameters. Both tube diameters include integral circular finning rolled from the tube wall to increase heat transfer.

L&M’s exclusive design ensures that Mesabi System Protector Tube and Shell Coolers can be quickly and simply returned to service if damaged or require regular maintenance. Held in headers with removable, flexible, fluorocarbon rubber seals, individual tubes are easily repairable in the field and can be returned to 100 percent cooling performance capacity. Mesabi System Protector coolers can be easily disassembled and cleaned internally and externally with high-pressure water.

L&M Radiator provides incomparable service to users and OEMs because all service is handled at the manufacturer level. In emergencies, L&M can ship most parts within 48 hours. Onsite technical and engineering assistance is available nearly anywhere in the world with a few days’ notice, thanks to manufacturing facilities and parts depots in the United States, Europe, Mexico, Chile, and Australia.

MESABI® System Protector™ Tube & Shell Coolers are covered by the L&M Radiator, Inc. General Warranty along with the following Product Specific Warranty:

L&M Radiator, Inc. warrants MESABI® System Protector™ Tube & Shell Coolers against seal leakage during normal operation for 48 months from date of invoice on new coolers.