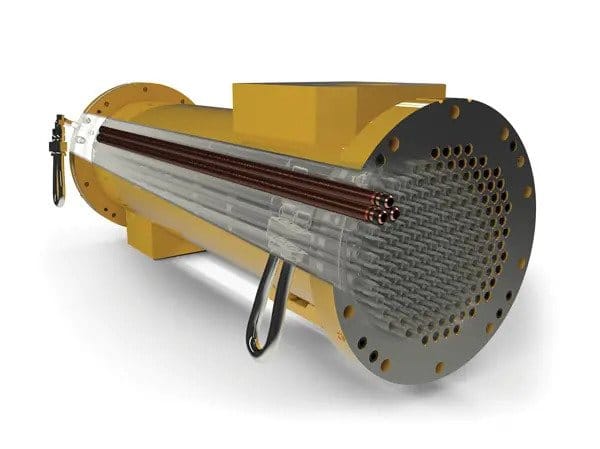

Tube And Shell Coolers

HIGHER COOLING PERFORMANCE POTENTIAL

IF APPLICATION REQUIRES HIGHER COOLING PERFORMANCE, SMALLER TUBE CONFIGURATIONS ARE AVAILABLE.

DUAL-SEAL SAFEGUARD

EACH TUBE END FEATURES TWO SEALS AND A COLLECTION CHAMBER TO PREVENT FLUID CROSS-CONTAMINATION.

NO LEAKY

SOLDERED SEAMS

MESABI® SEALS ABSORB STRESS, VIBRATION, SHOCK AND THERMAL EXPANSION.

100% REPAIRABLE

IN THE FIELD

INDIVIDUAL TUBES ALLOW FOR EASY IN-FIELD REPAIR. REFER TO RESOURCES FOR SERVICE VIDEOS.

MULTIPLE LEAK ALERTS

SIGHT GAUGE STANDARD WITH OTHER DETECTION OPTIONS AVAILABLE.

INDUSTRY BEST

SEAL WARRANTY

48-MONTH WARRANTY AGAINST SEAL LEAKAGE.

MAXIMUM

SERVICEABILITY

MINIMAL MAINTENANCE DESIGN FEATURES A CLEAN

OUT ACCESS DOOR FOR EASY AND EFFECTIVE

CLEANING FROM THE INSIDE OF THE SYSTEM.

MESABI® System Protector™ Tube & Shell Coolers are covered by the L&M Radiator, Inc. General Warranty along with the following Product Specific Warranty:

L&M Radiator, Inc. warrants MESABI® System Protector™ Tube & Shell Coolers against seal leakage during normal operation for 48 months from date of invoice on new coolers.

LARGE TUBE DIAMETER

RESISTANT TO TROUBLESOME CLOGGING.

100% REPAIRABLE

IN THE FIELD

INDIVIDUAL TUBES ALLOW FOR EASY IN-FIELD REPAIR. REFER TO RESOURCES FOR SERVICE VIDEOS.

NO LEAKY

SOLDERED SEAMS

MESABI® SEALS ABSORB STRESS, VIBRATION, SHOCK AND THERMAL EXPANSION.

INDUSTRY BEST

SEAL WARRANTY

48-MONTH WARRANTY AGAINST SEAL LEAKAGE.

GUARD AGAINST

THE ELEMENTS

AVAILABLE IN CORROSION-RESISTANT MATERIALS.

MESABI® RTTS® Tube & Shell Coolers are covered by the L&M Radiator, Inc. General Warranty along with the following Product Specific Warranty:

L&M Radiator, Inc. warrants MESABI® RTTS® Tube & Shell coolers against seal leakage during normal operation for 48 months from date of invoice on new coolers.