In metropolitan Australia, big-name railway companies rely upon Mesabi radiators to keep their trains running 24/7, 365 days a year.

Perth, Australia – Mesabi® radiators have been in service for more than 30 years with some of Australia’s most prominent railway companies.

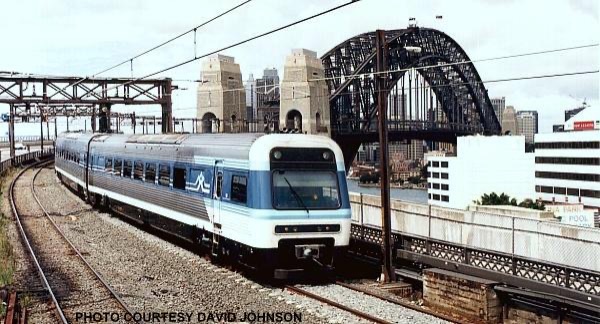

Yes, you read that right. Mesabi radiators built before the turn of the century can still be found on the New South Wales XPLORER and ENDEAVOUR trains.

For locomotives using non-Mesabi radiators, multiple decades of service is unheard of. So, what’s the secret? How can a Mesabi radiator do it?

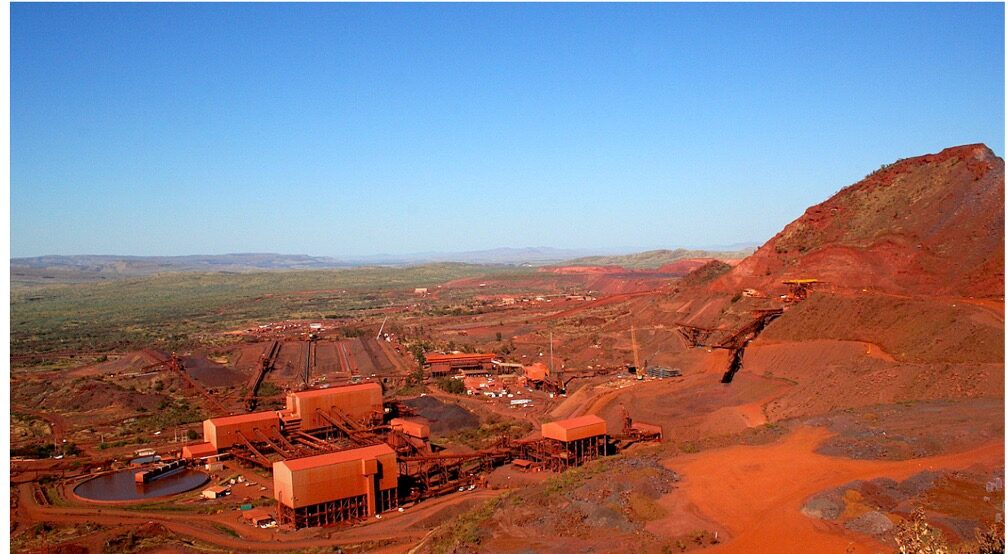

Well, it starts with engineering. Engineers and designers at L&M Radiator have spent the past 60 years perfecting and advancing designs to fit any and all applications. L&M is no stranger to working in various environments and conditions, paving the way for seamless operations in the mining, oil and gas, and forestry industries.

Passenger trains are no different. From decreasing downtime and overall operation expenses, to ensuring the safety and comfort of those on board, Mesabi consistently stands on reliability, durability, and longevity.

“When XPLORER first came back to us after that initial run, they asked for the ‘10-year radiators’ again. We all fell over because they were dead serious – but it’s true. Our radiators ran for 10 years without servicing. At the 10-year mark, we rebuilt a few of them, then, they went another 10 years. Another decade went by, and we did the same again,” said Richard Chapell, General Manager of L&M Radiator’s Australia operation.

The same case can be made for the locomotives with KiwiRail in New Zealand. Though currently decommissioned, their experience with Mesabi radiators reflects the true strength of its resilience in the railway industry.

“The last time I did a report on those locomotives at KiwiRail, it showed that they’d done more than 90,000 hours (about 10 years) with our Mesabi radiators and never put in downtime, other than an external washdown – but that was it! Those trains had several engines changed, but the radiators remained untouched,” said Tony Coppins, Sales Manager & Product Support Area Representative of L&M’s Australia operation. “We first did business with them over 30 years ago – that’s a pretty long life when you look at it.”

High Performance, 24/7, 365 Days a Year

The greatest test of strength for any radiator is its ability to perform in any given condition.

When it comes to the railway industry, specifically the passenger trains that run in and out of large cities througout Australia, these trains are chugging on a consistent and continuous route – twenty-four hours a day, seven days a week. Locomotive performance is of the utmost importance when it comes to the simple, day-to-day commute for passengers, relying on its efficiency as well as the safety it provides for transportation.

Now, a train operating in an urban area is a far cry from a coal mine or a landfill, but you would be surprised by the amount of dust and debris that passenger trains are subject to. Having a durable, dependable, easy-to-clean radiator is essential for long-lasting use.

“In a metropolitan area, especially somewhere such as Sydney, if you have passenger trains that are breaking down on a regular basis and passengers are getting stuck on platforms or in trains, it raises many concerns for their safety,” said Coppins. “Since we started working with rail companies in the area, I can’t recall hearing about a train breaking down.”

This is a testament to the strength and performance of Mesabi radiators. It’s no surprise that organizations such as Transport NSW Sydney Trains, the owner of the XPLORER and ENDEAVOUR diesel trains, kept coming back for more – Mesabi is just that good. And a Mesabi exceeds the given expectations of a radiator’s job, which is to primarily cool down and regulate engine temperatures.

“A radiator has to be able to do its job in very hot conditions, and in Australia, Mesabi radiators get pushed to the absolute limit,” said Chapell. “Our systems have to be able to cool the engine, otherwise the engines would be failing and not last a long time. We’re cooling all the time in Australia, as it never gets to freezing or below, so these conditions test the capability of the radiator to actually do its job.”

Mesabi Fights Thermal Expansion with Rubber Seals

Where Mesabi radiators by L&M Radiator really win out over the competition is in its design. Mechanically bonded cores, otherwise referred to as conventional cores, have core tubes which get implanted into header plates that are bolted into the tanks of the train. When these core tubes expand, they seal around the header plate, creating a solid piece. Here, as stress builds up when the locomotive moves along train tracks, the vibration often causes the area around the header plates to split and crack.

“Typically, this is where we see a lot of leaking take place, and that’s where Mesabi comes in. Our design creates these cores with rubber seals, so they sit and flex the whole time. They never break,” said Bob Chennell, Customer Service Manager of L&M Radiator Australia.

In addition to stress, thermal expansion often occurs on heavy moving trains, especially on those that operate in consistently hot weather. Australian rail cars are most susceptible to thermal expansion, causing material to expand and shift in response to heat, cracking tubes at those key weak corners of the header plates.

“When facing thermal expansion, vibration, and everything, that’s where Mesabi radiators prove themselves with their rubber seals and individual tubes, and their ability to handle the extreme heat, or extreme cold,” said Coppins.

XPLORER and ENDEAVOUR trains have been outfitted with Mesabi® Copper H-Tube Radiators. This specific design offers the precise, high-performing cooling solution for your needs. This model withstands thermal and mechanical stress, is easy to clean, and is 100% repairable in the field.

Similar to other industries involving heavy equipment, the railway industry manages and prioritizes cost viability. In operating passenger and freight trains, rail companies put a premium on longevity of cost-efficient expenses. The longer a radiator on a locomotive can run, the less money these companies will be spending. When a company gets stuck in a cycle of replacing its machines every five years, it negatively affects its choices in the long run.

“In the mining industry, engines take a beating and therefore, engine overhauls are a planned event – typically on a 3-5 year cycle. In the rail industry, it’s the same methodology, but over five years of life expectancy,” said Chapell. “So, when we talk about our radiators servicing these rail companies for over ten years, it says something about our product. Mesabi radiators aren’t just running longer, they’re extending the life of those trains.”

So, what are you waiting for? It’s time to change the way your machines perform, and there’s no better option to turn to than a Mesabi radiator.

L&M Radiator: Pumping Life Back into Australia’s Passenger Trains

For more information about Mesabi products, visit Products or www.Mesabi.com

For more stories similar to this one, visit The Mesabi Exchange.